Quartz Grits Storage

The typical design consists of 10 dedicated silos (10 m³ each), each one containing a specific mesh according to the production plan. The big bags are handled by means of an electric hoist, enabling the grits to be poured directly into the silos through raw material supporters on the top platform.

From the bottom of the silos, the grits are passed on to enclosed conveyors and are then transported to the weighing silos. From the weighing silos, precise quantities are discharged into shuttles or belt conveyor that feed the mixers.

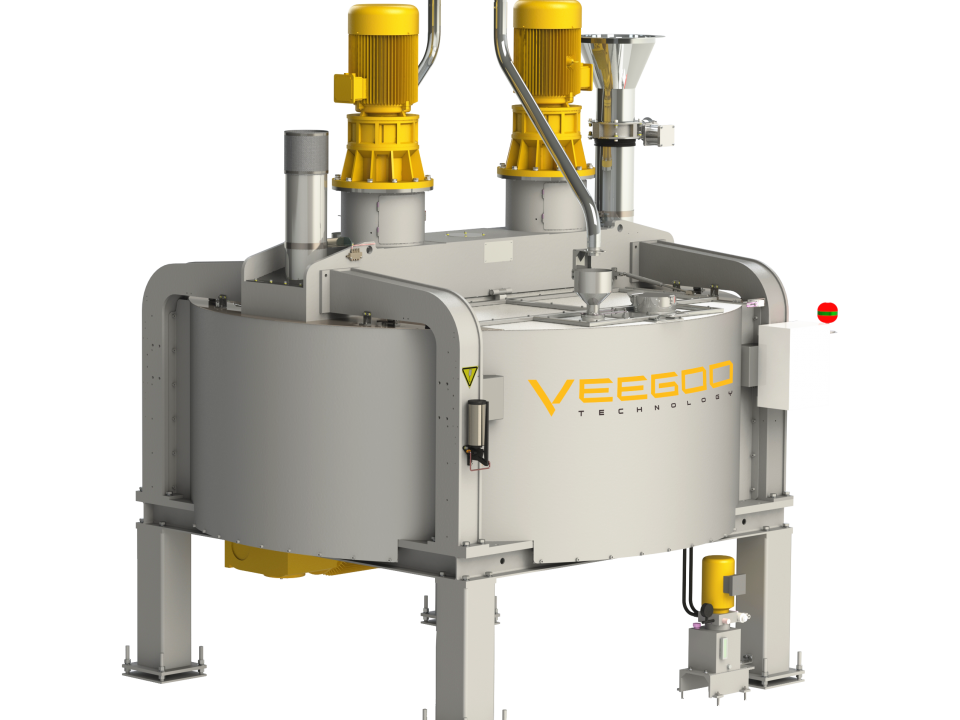

Quartz Automatic Weighing System

This is a very important section of the quartz line, responsible for quality and repeatability, the former depending greatly on the proportions of the formula components being correct. Repeatability, or reproducibility, simply means achieving constant quality and identical technical parameters among different production lots over time. VEEGOO takes special care to avoid any potential contamination by ensuring a "clean channel" for the powder and grits on their way from the silos to the mixers. This is made possible by the use of stainless steel components and

enclosed conveyors system only.